What is the principle of making circuit boards?

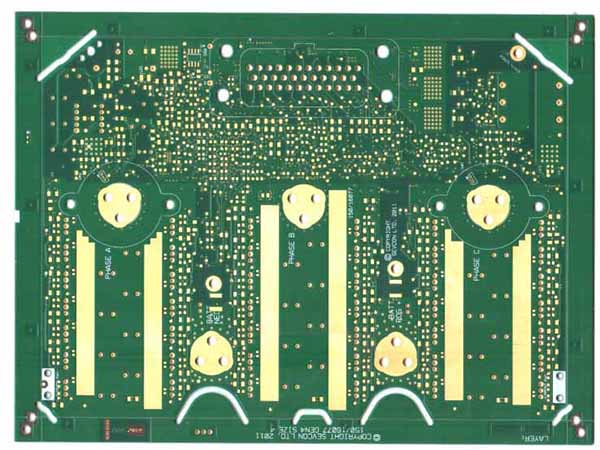

Circuit boards have a very important effect in the whole electronic products, so what is it? Simply speaking, it is for the need of high density and compressed space, many conductive lines are assembled and pressed together on one board, and then various components are assembled and welded to this board. It can be seen that it is complete. When all the electronic components are integrated, the circuit board is the first one to be questioned when the function of the electronic products is faulty. So how is PCB made? Today Jiangmen PCB manufacturer will give you a detailed introduction.

1. Preparing the copper clad sheet, epoxy resin sheet is one of the most widely used sheets, drilling holes on the copper clad sheet and manufacturing according to the orientation of the circuit board specifications.

2. Electroplating means conducting the holes with chemical copper, so that the two sides of the circuit can be connected as a whole.

3. Make a circuit on the copper plate. This process, also known as graphic handling, is to remove excess copper and make copper wires on the copper surface according to the planned route.

4. The next step is to do anti-welding, that is, anti-welding, which has the effect of protecting plates and lines.

5. Characters are also words. They are the marks of PCB assembly components. When you take apart your desktop computer, you can see such a board with words, which is the PCB we need, also known as PCB.

6. After the PCB is made, the size should be defined. Next comes the open-loop section, also known as moulding. It is cut into small pieces, and then tested its electrical performance to see if it can be turned on and if it is useful after power-on.

After completing the above process, the PCB is basically manufactured. After the PCB has been tested, the appearance of the PCB should be checked to see if there are any defects. Then the PCB can be packed and loaded into trucks.

The article originated from Jiangmen single-sided and double-sided circuit boards. http://m.jzfwq.com

-

07-18

What is the structure of blind buried hole circuit board?

Blind buried-hole circuit boards have the characteristics of free zigzag, folding and winding, free movement and expansion in three-dimensional space, good heat dissipation performance and high precis

-

07-18

What role does copper play in circuit boards?

PCB manufacturers take you to know that there are several reasons for PCB copper laying: 1. EMC can shield large area of ground or power supply copper, and some special areas, such as PGND, play a pr

-

07-18

Four matters needing attention in choosing PCB manufacturer

When choosing PCB manufacturers, the price of PCB manufactured by professional manufacturers will be more affordable, and the quality assurance will be stronger, which will be more guaranteed after

-

07-18

How to use three glue-proof PCB correctly?

Sanfang gum does not contain evaporative substances such as acetone and xylene, which is more environmentally friendly and safe. Mainly used in electronic circuits and components to form a protectiv