Reasons why tin is not easy to be deposited in the process of PCB patching

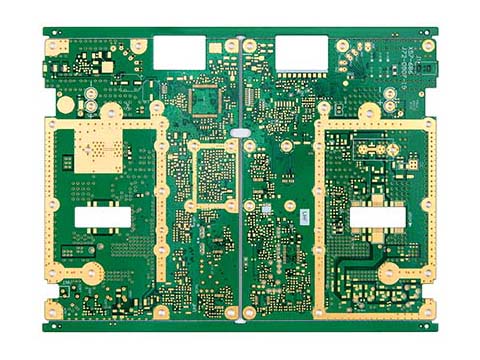

PCB production is a chaotic process. As the motherboard of products, PCB always bears more or less risks and responsibilities. Especially in the welding process of PCB, it is a process to test whether the touch between the motherboard and components is indispensable. If we don't pay attention to it, it will lead to poor or even impossible operation of the whole product.

PCB should be dust-free throughout the production process, especially in exposure, etching, subsequent tin spraying, gold deposition, testing, packaging process, must be dust-free, in order to avoid impurities on solder paste or pad, affecting welding. These processes will be strengthened to ensure zero complaint and response as the ultimate goal. Manual inspection process should pay attention to ensure that there is no sweat stain on the hands, as far as possible with gloves operation, including patch assembly personnel in the assembly before playing solder paste, as far as possible in the welding pad cleaning before welding, if the pad is very fine, the requirements are particularly stringent. As for gold-deposited circuit boards, special attention should be paid to the external air oxidation and sweat oxidation. Gold-deposited circuit boards are relatively easy to be oxidized. Welded manufacturers and customers try to ensure that the factory packaging of circuit boards manufacturers is in good condition before they are ready for patches. Do not easily dismantle vacuum packaging, otherwise the oxidation of future patches will become difficult.

Tin spraying circuit boards should pay attention to ensure the cleanliness and tidiness of the tin surface, especially to ensure the level of the tin surface. Tin spraying will be waterlogged, which is caused by the clean and unclean tin surface, and should be reworked. Tin surface roughness should be formed by improper operation during tin spraying and should be adjusted in time. SMT patch manufacturer should pay attention to cleaning tin surface as far as possible before welding. Fine pad should ensure full tin distribution during welding, and flux welding should be added when conditions permit. Environmental protection products are generally required now, so the factory is lead-free tin, lead-free PCB will form welding difficulties, welding time can increase the appropriate flux to assist PCB solder pad tin saturation.

If slight oxidation is found in the welding of gold-deposited PCB before welding, it should be scrubbed with alcohol first and then welded with flux. Normally it doesn't cause too much problems.

The article originated from Jiangmen single-sided and double-sided circuit boards. http://m.jzfwq.com

-

07-18

What is the structure of blind buried hole circuit board?

Blind buried-hole circuit boards have the characteristics of free zigzag, folding and winding, free movement and expansion in three-dimensional space, good heat dissipation performance and high precis

-

07-18

What role does copper play in circuit boards?

PCB manufacturers take you to know that there are several reasons for PCB copper laying: 1. EMC can shield large area of ground or power supply copper, and some special areas, such as PGND, play a pr

-

07-18

Four matters needing attention in choosing PCB manufacturer

When choosing PCB manufacturers, the price of PCB manufactured by professional manufacturers will be more affordable, and the quality assurance will be stronger, which will be more guaranteed after

-

07-18

How to use three glue-proof PCB correctly?

Sanfang gum does not contain evaporative substances such as acetone and xylene, which is more environmentally friendly and safe. Mainly used in electronic circuits and components to form a protectiv